Coloured Aluminium Pigments: Characteristics and Applications

Release time:

2025-06-05

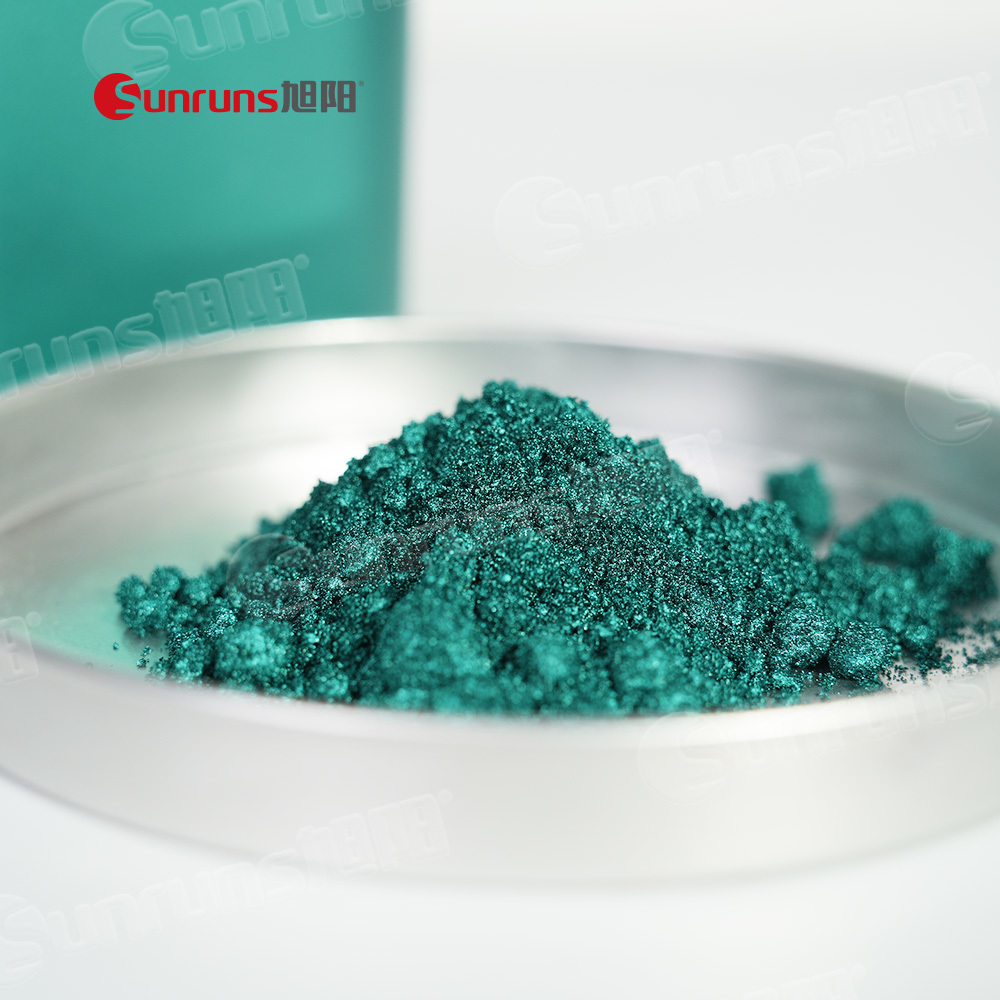

Coloured aluminium pigments combine the brilliance of metallic flakes with vibrant or subtle hues, offering a unique visual effect that enhances both functional and decorative coatings. Used in plastics, paints, inks, and industrial finishes, these pigments balance metallic shine with controlled colouration for specialised visual and performance outcomes.

Coloured aluminium pigments combine the brilliance of metallic flakes with vibrant or subtle hues, offering a unique visual effect that enhances both functional and decorative coatings. Used in plastics, paints, inks, and industrial finishes, these pigments balance metallic shine with controlled colouration for specialised visual and performance outcomes.

1. What Are Coloured Aluminium Pigments?

Coloured aluminium pigments are aluminium flakes coated with transparent or semi-transparent colourants, often achieved through organic dyes, inorganic pigments, or metal oxide layers. Unlike standard silver aluminium flakes, coloured variants retain metallic brilliance while introducing tinted or chromatic effects.

2. Key Characteristics

2.1. Metallic Gloss with Colour Depth

These pigments provide a duochrome or pearlescent appearance, combining reflective aluminium with colour overlays that change with the angle of light.

2.2. Controlled Leafing Behaviour

Depending on surface treatment (e.g., stearic acid or oleic acid), coloured aluminium pigments can be leafing (floating at the surface of the film for maximum reflectivity) or non-leafing (dispersing evenly through the binder for depth).

2.3. Chemical Compatibility

Coloured pigments are engineered for compatibility with solvent-based, waterborne, or UV-curing systems, depending on the end application.

2.4. Colour Stability

Advanced coating technologies ensure good UV stability, weather resistance, and chemical resistance, important for outdoor or high-performance use.

2.5. Particle Size Flexibility

Available in various flake sizes, from fine (<15 µm) to coarse (>50 µm), offering options for silky smooth finishes to sparkling metallic looks.

3. Applications of Coloured Aluminium Pigments

3.1. Automotive Coatings

Used in both OEM and refinish markets, these pigments provide luxury finishes, colour-shifting effects, and high-gloss appearances with depth and sparkle.

3.2. Plastic Masterbatches and Compounds

Ideal for packaging, consumer goods, and cosmetic containers, coloured aluminium pigments impart visual appeal without compromising moulding performance.

3.3. Industrial Coatings

They’re used in appliances, bicycles, and electronics for durable, decorative finishes with resistance to wear and corrosion.

3.4. Printing Inks

In gravure, screen, and flexographic printing, coloured aluminium pigments create eye-catching labels, gift wraps, and security printing effects.

3.5. Decorative Paints and Cosmetics

In nail polish, eye shadows, or wall coatings, they offer a metallic sheen with a coloured twist for premium aesthetic outcomes.

4. Advantages Over Traditional Pigments

-

Higher Reflectivity than coloured mica or pearlescent pigments

-

Greater Colour Customisation via transparent overlays

-

Dimensional Effects from flake orientation and layering

-

Excellent Processability in coatings, plastics, and inks

Previous

BE THE FIRST TO KNOW

Search historyclear all records

- 全部

- 产品管理

- 新闻资讯

- 介绍内容

- 企业网点

- 常见问题

- 企业视频

- 企业图册

Sign up for Our Newsletter

Sunrise

Online message