Bronze Pigment

Bronze Pigment

Key word:

Copper

Gold Powder

Metallic effect

High brightness

Category:

Bronze Pigment

Accessories:

Details

Product Introduction

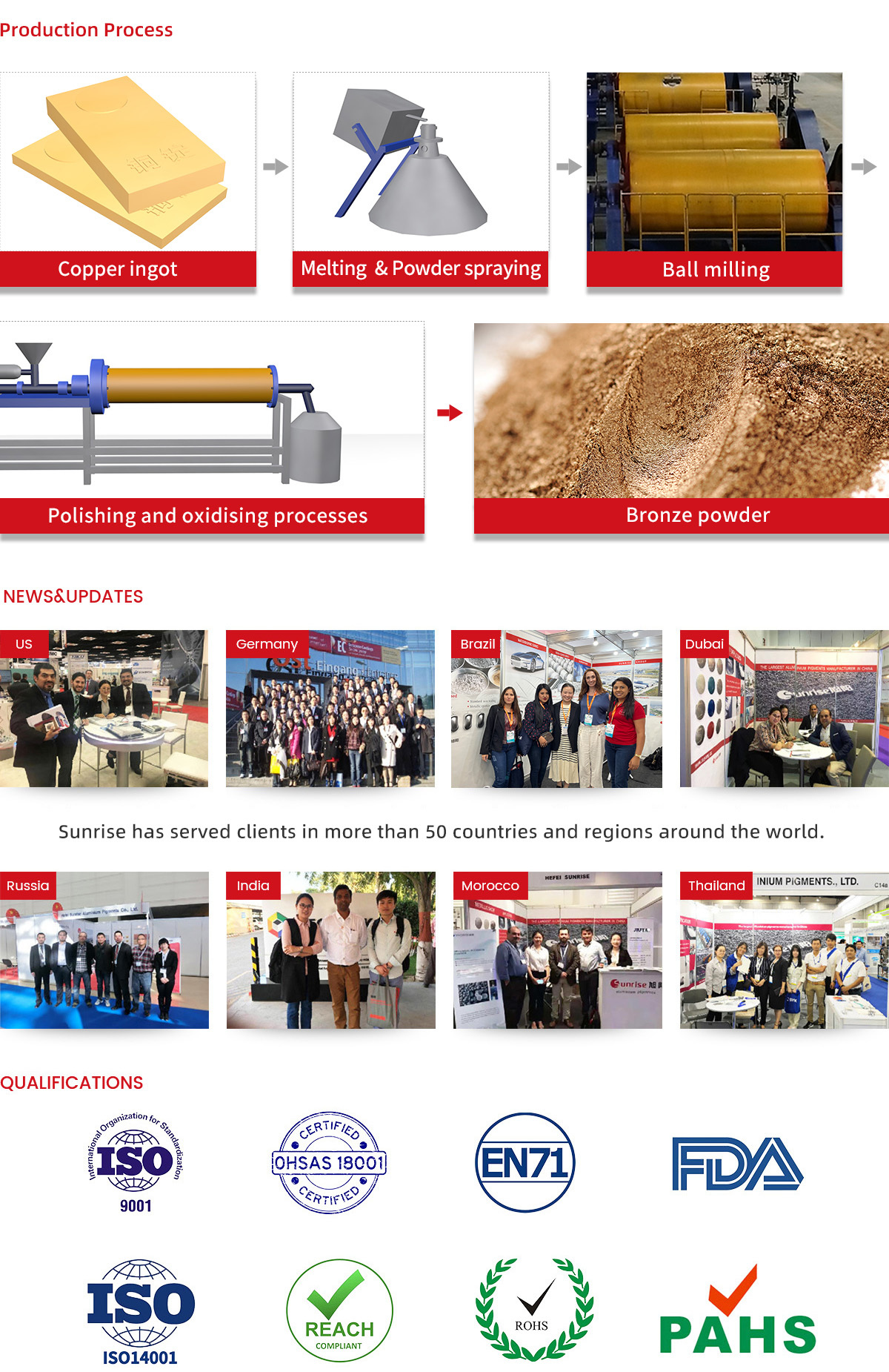

Bronze powder, also known as copper-zinc alloy powder or gold powder, is an extremely fine, flake-like metal powder processed through smelting, powder spraying, ball milling, polishing, and oxidation of copper and zinc as the main raw materials. Copper alloys can exhibit various colors on the surface, including red, golden yellow, white, and even purple, depending on the composition. The color shade of bronze powder varies with the zinc content. When the zinc content is below 10%, it produces a light gold effect, known as pale gold; when it is between 10% and 25%, it produces a rich light gold effect, known as rich pale gold; when it is between 25% and 30%, it produces a rich light gold effect, known as rich gold.

Performance Parameter of Bronze Powder

| Grades | Shades | D-50 Value | Water Coverage | Characteristics | Application |

| 220Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 36-40 | 2500-3500 | High Brightness Strong Metallic Effect |  |

| 400Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 23-27 | 3500-4500 | High Brightness Strong Metallic Effect |  |

| 600Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 16-20 | 4000-5000 | High Brightness Strong Metallic Effect |  |

| 800Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 13-15 | 4500-5500 | High Brightness |  |

| 1000Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 9-11 | 6000-7000 | Fine High Brightness |  |

| 1200Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 6-8 | 7000-8000 | High Brightness |  |

| 1500Mesh | Pale Gold/Rich Pale Gold/Rich Gold | 2-4 | 10000-13000 | High Brightness Good Stability |  |

| Gravure Printing | Pale Gold/RichPale Gold/Rich Gold | 36-40 | 3000-4000 | High Brightness Strong Metallic Effect |  |

| Gravure Printing | Pale Gold/Rich Pale Gold/Rich Gold | 23-27 | 4000-5000 | High Brightness Strong Metallic Effect |  |

| Gravure Printing | Pale Gold/Rich Pale Gold/Rich Gold | 16-20 | 4500-5500 | High Brightness Strong Metallic Effect |  |

| Gravure Printing Powder | Pale Gold/Rich Pale Gold/Rich Gold | 6-8 | 8000-10000 | High Brightness Excellent Hiding Good Flake Structure |

|

| Gravure Printing Pellets | Pale Gold/Rich Pale Gold/Rich Gold | 6-8 | / | Dust-free Easy to Disperse |  |

Performance Parameter of Bronze Powder

| Grades | D-50 Value | Water Coverage | Characteristics | Application |

| 800Mesh | 13-15 | 4500-5500 | High Brightness |  |

| 1200Mesh | 6-8 | 7000-8000 | High Brightness |  |

Precautions

1. Floating Properties: Ordinary bronze powder typically has good floating properties, meaning it naturally rises to the surface. It is usually unnecessary to add wetting agents or dispersants, as these can reduce their floating properties and diminish the metallic effect.

2. Adjusting Floating Properties: If adjusting the floating properties of the bronze powder is necessary, adding 0.1-0.5% citric acid can reduce the floating force. However, this will also decrease the metallic effect.

3. Enhancing Optical Effect: If the desired optical effect is not achieved after adjusting application viscosity and drying time, a small amount of surface lubricant and levelling agent can be added.

4. Redispersibility: Generally, bronze powders exhibit good redispersibility. In case of precipitation, less than 2.0% of anti-settling agents or thixotropic agents, such as bentonite or fumed silica, can be added to the formulation.

5. Storage: Bronze powder and its finished products should be stored at room temperature in a dry environment. Any unused bronze powder should be sealed immediately, as prolonged exposure to air can cause oxidation and deterioration.

6. Resin Compatibility: Avoid using nitrocellulose and epoxy resins, as they can chemically react with copper, forming gelatinous substances. If these resins must be used, they should be applied as quickly as possible.

7. Resin Selection: Select resins with an acid value of less than 3 whenever possible. The lower the acid value of the resin, the better it will perform in the system.

8. Solvent Selection: Aromatic hydrocarbon and ester solvents are recommended for wetting copper gold powder particles completely and achieving thorough dispersion. Avoid using alcohols, ketone solvents, and poorly acidified lipid solvents.

Applications

Related Products

Online message

Please fill out the form below and we will contact you as soon as possible.

BE THE FIRST TO KNOW

Search historyclear all records

- 全部

- 产品管理

- 新闻资讯

- 介绍内容

- 企业网点

- 常见问题

- 企业视频

- 企业图册

Sign up for Our Newsletter

Sunrise

Online message