Why Waterborne Coatings Choose Aluminum Paste?

Release time:

2025-09-23

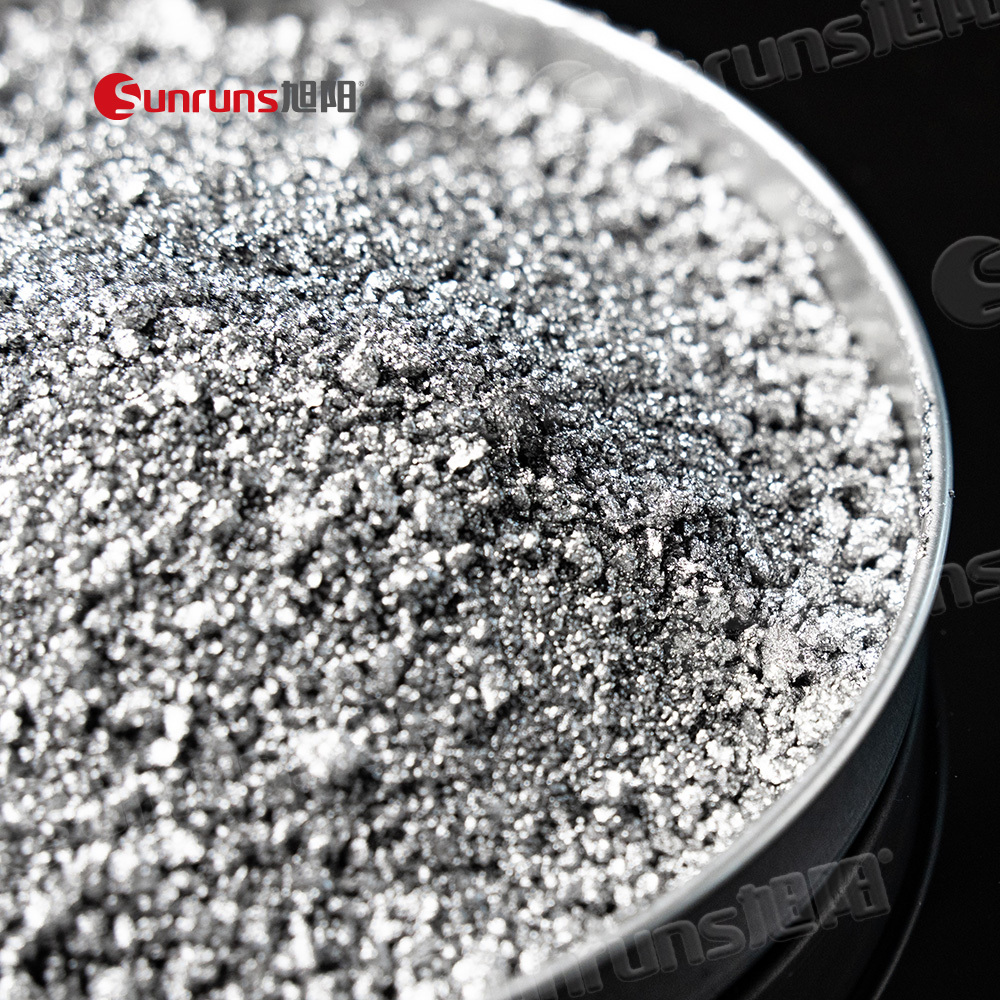

The coatings industry is undergoing a significant shift towards sustainability, driven by stringent environmental regulations and growing consumer demand for eco-friendly products. In this transition, waterborne coatings have emerged as a leading alternative to traditional solvent-based systems. A key challenge, however, has been replicating the brilliant metallic effects achieved with solvent-based metallic pigments. This is where aluminum silver paste plays a pivotal role.

The coatings industry is undergoing a significant shift towards sustainability, driven by stringent environmental regulations and growing consumer demand for eco-friendly products. In this transition, waterborne coatings have emerged as a leading alternative to traditional solvent-based systems. A key challenge, however, has been replicating the brilliant metallic effects achieved with solvent-based metallic pigments. This is where aluminum silver paste plays a pivotal role.

1. Excellent Metallic Aesthetic Effect

The primary reason for using aluminum paste is its unparalleled ability to create a bright, silvery metallic luster and a sense of depth. The tiny, flat aluminum flakes align parallel to the coating surface, reflecting light uniformly to produce a brilliant, mirror-like effect. This enhances the visual appeal of products, from automotive parts to consumer electronics, making them look more premium and technologically advanced.

2. Environmental and Safety Advantages

This is the most compelling driver. Waterborne coatings use water as the primary dispersing medium, significantly reducing the emission of Volatile Organic Compounds (VOCs). Aluminum pastes designed for water-based systems are inherently compatible with this environment. They are typically manufactured with special surface treatments, making them more stable in water and eliminating the need for large amounts of harmful solvents. This results in a safer working environment for applicators and a smaller ecological footprint.

3. Corrosion Resistance and Weatherability

Sunrise Aluminum flakes provide a unique protective quality. When properly oriented in the coating film, they create a layered, "leafing" effect that acts as a physical barrier. This barrier shields the underlying substrate from moisture, oxygen, and UV radiation, significantly enhancing the coating's corrosion resistance and durability. This is crucial for applications exposed to harsh weather conditions, such as automotive coatings, architectural facades, and industrial machinery.

Previous

BE THE FIRST TO KNOW

Search historyclear all records

- 全部

- 产品管理

- 新闻资讯

- 介绍内容

- 企业网点

- 常见问题

- 企业视频

- 企业图册

Sign up for Our Newsletter

Sunrise

Online message